Residential vs. Commercial Electrical Wiring: 6 Key Differences

You don't need to be an electrician to know there's a major difference between the wiring behind your bedroom wall and the system powering a full-scale office building.

While both residential and commercial electrical wiring are designed to deliver electricity safely and consistently, that's pretty much where the similarities end. The scale, structure, materials, and code requirements all vary depending on how and where that electricity is being used.

Whether you're a homeowner planning a renovation or a business owner building something from scratch, understanding these differences helps you stay ahead of problems before they even start.

If you've ever wondered why commercial wiring looks, feels, and behaves differently than what you're used to at home, here's what's going on behind the scenes, and these six key differences matter more than you think.

Voltage and Phase Type

The voltage delivered in residential and commercial systems is one of the first major dividing lines. Most homes operate on single-phase power, providing 120 to 240 volts. That's more than enough for standard appliances, lighting, and HVAC systems in a home setting.

Commercial buildings, on the other hand, typically run on three-phase power, which can deliver significantly higher voltages, often 277/480 volts.

This configuration is more stable, efficient, and better suited for heavy machinery, elevators, industrial HVAC, and large-scale lighting systems. The three-phase system also minimizes voltage drop and offers more consistent performance across long distances and larger buildings.

If you're running a commercial facility without a proper three-phase setup, you would be underpowered, creating operational risks and inefficiencies that could cost you in the long run. The power source defines everything that comes next.

Materials and Insulation

In residential wiring, affordability and ease of installation drive the choices.

This is why most homes use NM cable, also known as Romex. It's a flexible, plastic-sheathed cable that works well in wood-framed structures with drywall. But in commercial buildings, conditions are tougher and demand more protection. That's where conduit systems come in.

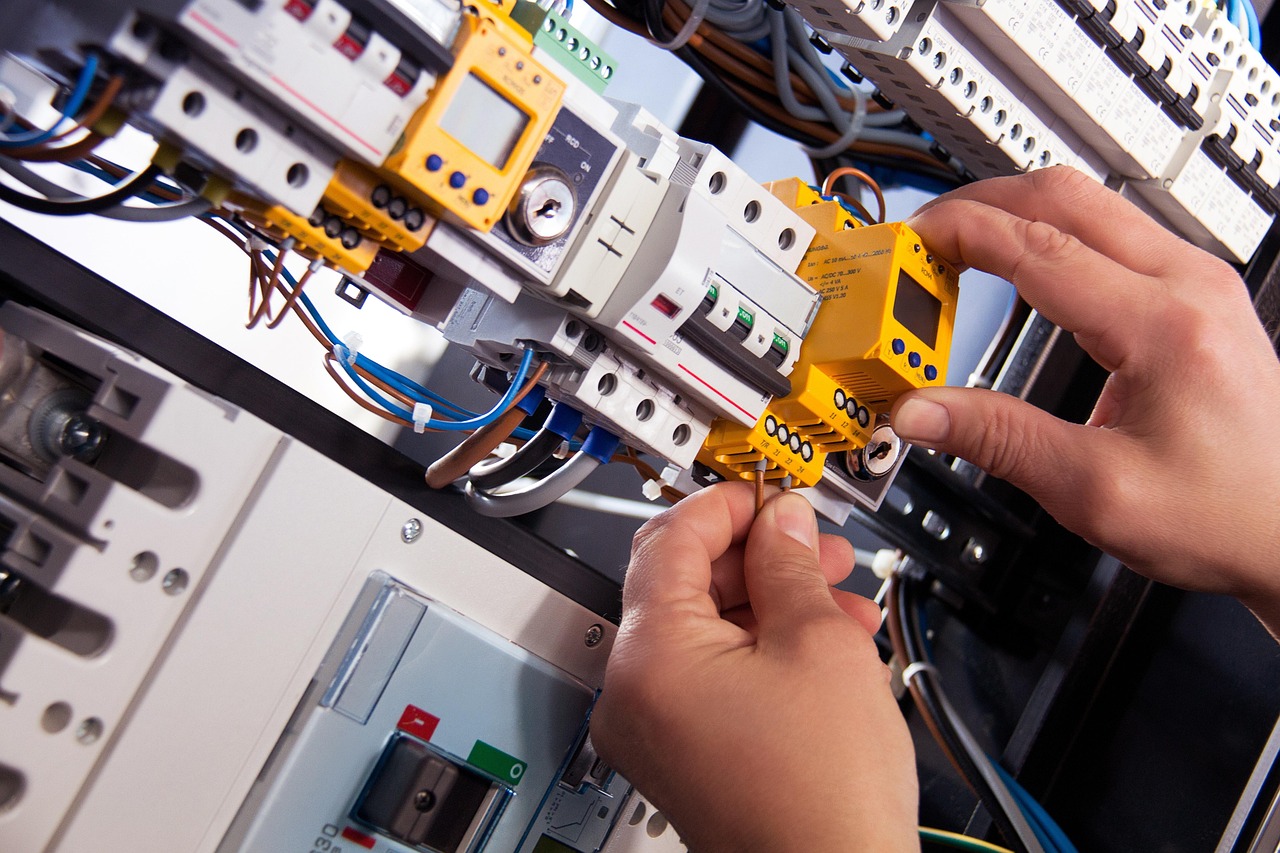

Commercial Charlotte electricians or in any other city, use THHN or THWN wires inside metal or PVC conduits, offering better durability, insulation, and protection from physical damage.

You're also more likely to see plenum-rated insulation in commercial settings, materials that are flame-retardant and emit low smoke, especially in air return spaces.

This is not something you typically worry about in a home, but it's a major code requirement in commercial jobs. Here it's not about aesthetics, it's about performance and long-term safety.

If commercial wiring fails, it affects multiple systems and possibly dozens of people. That's why the materials used are stronger, more heat-resistant, and built for high-demand environments.

Code Compliance and Safety Standards

Both residential and commercial wiring follow the National Electrical Code (NEC), but that's just the baseline. In commercial construction, the codes are interpreted more strictly, with added layers of local, state, and industry-specific requirements.

You'll find mandates for fire suppression wiring, emergency lighting, dedicated circuits for equipment, and backup power integration, all of which may be optional or unnecessary in residential homes.

Commercial inspections are also far more rigorous. Inspectors look for accessibility, labeling, load calculations, and even system scalability. It's not just about “does it work?” It's about “can it perform safely under worst-case conditions?”

Residential code requirements still matter, especially during renovations, but they're typically focused on ensuring basic safety and energy efficiency for small-scale living.

In a commercial setting, wiring must account for higher occupancy, legal liability, and future-proofing for business growth. When the risk is greater and the space is more public, the standards get tighter for good reason.

Load Demand and Electrical Capacity

Your home's electrical demand is fairly predictable: kitchen appliances, laundry machines, lights, and maybe a hot tub or EV charger. It's manageable. But commercial buildings are another story entirely. Their load demands can spike dramatically based on equipment, lighting systems, HVAC, and even operating hours.

This is why commercial panels are built for higher amperage and come with room for growth. It's common to see 400-amp or even 800-amp panels in commercial buildings, compared to the 100 or 200 amps typical in homes.

Commercial wiring also involves detailed load calculations based on square footage, usage type, and occupancy. Everything must be balanced across three phases to avoid overloading one side of the system.

This level of foresight simply isn't required in a home where loads rarely fluctuate at scale. In short, commercial electrical systems must be ready to expand, adapt, and support mission-critical systems without failure. The stakes and the complexity are significantly higher.

Installation Practices and Accessibility

Residential wiring is typically hidden within walls, floors, or ceilings, following a straightforward path through wooden studs and joists. It's designed to be out of sight, out of mind. But commercial wiring must often remain accessible for inspections, upgrades, or system maintenance.

This is why you often see exposed conduit in industrial ceilings, drop ceilings with wire trays, or surface-mounted raceways in office buildings. This is done for both convenience and regulation.

In commercial settings, everything from labeling to spacing is governed by strict guidelines that ensure systems can be easily identified and maintained. It's a practical response to scale. You can't shut down an entire facility just to access a single wire buried in drywall.

Commercial installation is more modular, more visible, and much more standardized. Residential wiring can afford to be flexible and hidden, but commercial systems demand transparency and structure to operate safely and efficiently in real-world conditions.

Backup Power and System Redundancy

In most homes, backup power is optional. A generator or battery system might be installed for emergencies, but it's not usually built into the original wiring plan.

Commercial buildings, however, are often required by code to include backup power systems, especially in settings like hospitals, schools, restaurants, or data centers.

These systems are wired directly into the infrastructure, with separate panels, transfer switches, and critical load circuits that automatically switch over in the event of an outage. It's about protecting data, inventory, and human safety.

Commercial electricians must plan for system redundancy from the start. That means accounting for UPS systems, generator capacity, and compliance with emergency power timelines. In contrast, residential systems focus more on comfort during outages than continuity.

For businesses, power isn't a convenience; it's the backbone of operations. This difference shows up clearly in how each system is wired from day one.

Final Thoughts

Residential and commercial wiring may share some components, but their goals, demands, and requirements couldn't be more different.

From the voltage flowing through the walls to the level of planning involved behind the scenes, each system is tailored to its environment.

Commercial wiring prioritizes durability, compliance, scalability, and uptime. Residential wiring focuses on comfort, efficiency, and straightforward usability. Understanding these differences helps ensure each space, whether it's your home or your business, runs exactly the way it should.

Published 7/28/25